AyMINE – Technical documentation

sys

- Translations

- System Management

- User Administration

- System User

- Documents and files

- System Groups and Teams for rights settings

- Record Relationships

- Client

- Dashboard

- Public link to the document

- Client settings

- Revisions and comments

- User administration

- Copying and moving files between objects

- Object location on the board

- Additional functions with files

- Client items

- Picture presentation

- Secure login to the sytem

- Configure gateways for external messages

- Connecting users to VOIP PBX

- Call directly from CRM

- Send SMS directly from CRM

- Formatted texts in the application

- Secure business communication

- System Configuration

- User Processes

- Processes in use

- Message with the outside world

- Email messages

- Relation types

- Securing posts and internal discussions

- Recent Files

- Crypto Wallet

- Electronic sign even on mobile device

tsk

- Required qualifications

- Package definition

- Phrases and terms

- Data Area

- Test

- Risk

- Task

- Business event

- Task, project & quality management

- Records and protocols

- Directives and Policies

- Events

- Risk Pattern

- Information

- Meeting

- Problems, tickets and their management

- Plan template / strategy

- Decision

- Configuration Package

- Record template

- Change management process in a project

- Task list

- Requirements

- Team Member

- Right to Manage Qualifications

- Input requirements

- Obligation

- Competencies and Skills

- Project definition

- Activity log

- List of event instances

- Task patterns saves work and improve quality

- Methodology and Quality Management systems

- My Tasks

- Task planning both in project and daily business

- Project Team

- Events and meetings

- Sample tasks and methodologies of the area

- Events and meetings

- List of event instances

- Client Settings

- Processed objects

- Mark patterns

- Manage your marks

- Region / project / methodology

- Personal calendar

- Objects of decision making

- Event activation buttons

- Objects affected by the problem

- Variant decision-making

- Recorded activities

- Self-Reminders

- Assigning a new task

- Objects related to the task pattern

- Effect of the task on the right to modify the attached object

- Level of Competence

- Manager approval with the task report

- Requirements waiting for you

- Notification events

- List of business areas

- Qualification of user or contact

- Activation buttons

- Why some data can't be deleted

- Starting events

- Qualification of user or contact

- My projects

- Objects processed in the task

- Project

- Reminders and Messages

- Notification events

- Objects of decision making

- Starting events

- Sample tasks and methodologies of the area

- Activation buttons

- Records managed by a project

- Timesheet

- Project role

- What makes up the methodology / SMJ

- Drag & Drop between records

- Location

- My areas

- Kanban Task Overview

- Personal Task

- Internal helpdesk

- Customer Care Centre

- Project baseline

- Return project plan by baseline

- Project Schedule

- Type of tests

- The person responsible for the task

- Deals / Contracts

- Customer Service Response Generation

- 8D report - tool for problem resolution

- Task Scheduling

- Administration of the Task Management Module

- Adminitration of areas, projects, calendars

- Discussion

- GDPR and record of qualifications

- System rights for the task management module

- Project Planning

- Employee Tasks

- Incident and Quality Issue Management

- Collaborative Resolution of Multiple Problems

- Notice – example of use

- FMEA criteria for detection evaluation

- FMEA system functionality analysis

- Methodology how to conduct FMEA

- FMEA analysis of the failure occurence

- Analysis of the FMEA Severity

- FMEA Analysis

- Management of responsibilities - RACI Matrix

- RACI Matrix for Project

- Improvements and Preventive Measures

crm

- Directory or people and companies

- Address books

- Contact per person or company

- Order overview for customer groups

- Customer Order Overview

- Message patterns

- Quickly available contacts

- Contacts and directories module (

- Address book list and management

- Privacy policy

- Groups of contacts

- System Permissions and CRM Module Settings

- Contracts

- Send bulk messages in compliance with GDPR

- Bulk email footer

- Bulk Emails

- Partner in a contract

- Unsubscribe and set preferences

for bulk mail - How to correctly forget a person's details

am

- Product Categories

- Shared analytical model accelerate your project and development

- Products, assets and sales

- Products and Goods

- Tendering and purchasing

- Product Supplier

- Product status and change

- Project Goal

- Business Offer

- Recalculate bid

- Pricing

- Pricing – volume discounts

- Offers summaries

- Order Reports

- Quality criteria

- Creating and processing orders

- Product or Product Property

- Why are the Quality criteria usefull

- DFEMA - FMEA of the product design

- HARA for product

- Offer and Price Access Rights

- Product Units

- System order status query

frm

- List of records

The AyMINE Framework Module

The AyMINE Framework Module- AyMINE releases

- AyMINE – Initial advice

- AyMINE Modules

- Object locks

- Configure how your system looks and works

- Filtering in the list of records

- Icons in AyMINE

- Deleting

- Your main dashboard

- Object lists

- More about how the system works

- Object detail

- Private notes and tags for objects

- ClipLink

- Gestures and keyboard shortcuts

- Drag & Drop between records

- System rights

- AyMINE (C) 2020

- Gestures and Keyboard Shortcuts

- Password retention policy

- framework user rights

- AyMINE — Windows Application

- AyMINE — Tips for Mobile Usage

- Overview of Modules and Record Types

hr

- Human resources

- Worker

- Human Resources module security

- Personalistics – User Permissions and roles

- Manage department / division data

- Synchronizing staff and system users

- Responsible HR Manager

- HR module role

- Registration of job seekers

- An overview of your staff

- Digital Personnel Archive

- Job Position

- Worker overview

FMEA – Probability of Detection

FMEA – Probability of Detection

Probability of detecting a failure if it has occurred.

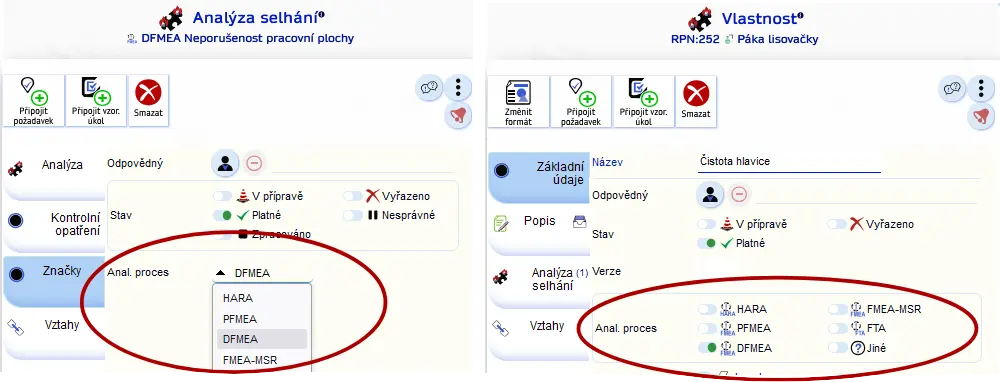

The definition varies for different types of FMEA analysis. Therefore, it is necessary to specify the type of analytical process (for individual failures or for properties).

The following overview is based on the automotive industry standard. Before using, check whether it is relevant for your case!

DFMEA

- Level 1: It is known that the design cannot fail

- Level 2: Verified standard procedures, aging control

- Level 3: Verified standard procedures, failure test

- Level 4: Verified standard procedures, function pass test

- Level 5: Verified standard procedures in the late development phase, aging control

- Level 6: Verified standard procedures in the late development phase, failure test

- Level 7: Verified standard procedures in the late development phase, low, function pass test

- Level 8: New test procedures are used, which are not verified

- Level 9: Known tests are not specifically designed to verify potential failures

- Level 10: Test procedures have not yet been developed

PFMEA

- Level 1: Failure is virtually impossible or cannot go undetected

- Level 2: Proven reliable detection methods; machine inspections prevent the occurrence of defective products

- Level 3: Proven detection methods; defective products are automatically detected

- Level 4: Proven detection methods; reliable inspections detect the problem during production and reject defective products

- Level 5: Verified inspections; semi-automatic detection alerts the operator

- Level 6: Verified inspections; manual inspection of products or samples detects defects

- Level 7: Unverified inspections; semi-automatic detection alerts the operator

- Level 8: Unverified inspections depend on manual inspection of products or samples to detect defects

- Level 9: It is unlikely that inspections will detect the problem; sample checks may not easily identify the issue

- Level 10: It is unlikely or impossible to detect the issue through inspections

FMEA-MSR

- Level 1: Always detected – significantly more than 99.9%; the system responds to failures

- Level 2: Detected with probability > 99.9%, the system is very likely to identify the failure

- Level 3: Automatic detection identifies failures with probability > 99% with a short response time, automatic reaction is highly probable

- Level 4: Detection with probability > 97% with medium response variability; the system will usually react to failures

- Level 5: Detection with probability 90–97%, with moderate response variability; the system will usually respond automatically to failures

- Level 6: The failure is detected by the user or system with probability > 90% and will likely be able to respond

- Level 7: Low probability that the user will recognize and respond; diagnostics reveal the problem with >60% accuracy.

- Level 8: Rarely possible to detect the problem, diagnostics detect failure with < 60% accuracy; user may not always respond

- Level 9: Failure will almost never be detected; system or user response cannot be relied upon

- Level 10: Cannot be detected; no response during operation